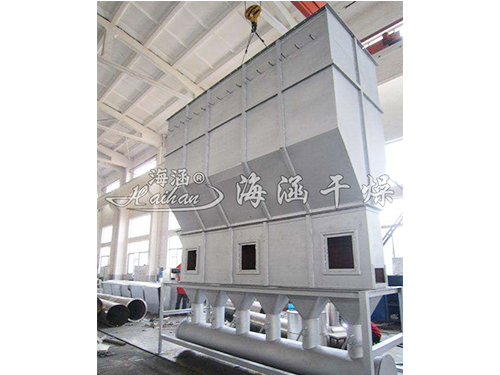

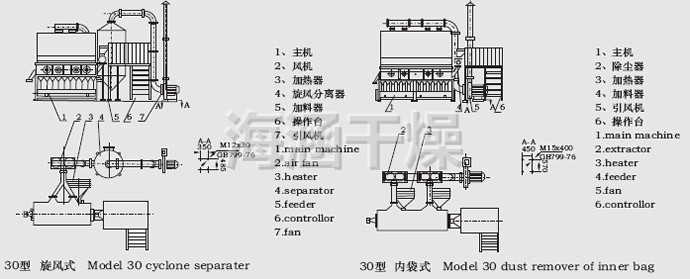

Category: Drying equipment series

Introduction: Working PrincipleThe clean hot air is distributed into the bed through the valve plate, and the wet material entering from the feeder is formed into boiling state by the hot air. As the hot air is in contact with the material, the process of heat and …

+86-13906119320

+86-13906119320

The clean hot air is distributed into the bed through the valve plate, and the wet material entering from the feeder is formed into boiling state by the hot air. As the hot air is in contact with the material, the process of heat and mass transfer is enhanced, so it can be dried in a short time. If the continuous type is used, the material enters from one end of the bed, boils and dries after tens of seconds to minutes, and automatically flows out from the other end of the bed. This equipment is generally operated under negative pressure.

|

Specification

Technical Parameters |

XF0.25-1

(rawXF10)

|

XF0.25-2

(rawXF20)

|

XF0.25-3

(rawXF30)

|

XF0.25-6 | XF0.3-2 | XF0.3-4 | XF0.3-6 | XF0.3-8 | XF0.3-10 | XF0.4-4 | XF0.4-6 |

| Bed floor area(m2) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 |

| Drying capacity(kg h2O/h) | 10-15 | 20-25 | 30-45 | 52-75 | -30 | 42-60 | 63-90 | 84-120 | 105-150 | 56-80 | 84 |

| Fan power(kw) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 |

| inlet temperature(oC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| material temperature(oC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

| Overall dimensions (main unit) L×W×H(m) | 1×0.6 | 2×0.6 | 4×0.6 | 6×0.6 | 2×0.70 | 4×0.7 | 6×0.7 | 8×0.7 | 10×0.7 | 4×1 | 6×1 |

| footprint (of a building, piece of equipment etc)(m2) | 18×3.35 | 25×3.35 | 35×3.35 | 40×3.35 | 25×3.4 | 38×3.4 | 45×3.4 | 56×3.4 | 70×3.4 | 18×3.58 | 56×3.58 |

|

Specification

Technical Parameters |

XF0.4-8 | XF0.4-10 | XF0.4-12 |

XF0.5-4

(原XF50)

|

XF0.5-6 | XF0.5-8 | XF0.5-10 | XF0.5-12 | XF0.5-14 | XF0.5-16 | XF0.5-18 |

| Bed floor area(m2) | 3.2 | 4.0 | 4.8 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 |

| Drying capacity(kg h2O/h) | 112-160 | 140-200 | 168-240 | 70-100 | 140-200 | 140-200 | 175-250 | 210-300 | 245-350 | 280-400 | 315-450 |

| Fan power(kw) | 44 | 66 | 66 | 30 | 66 | 66 | 90 | 90 | 150 | 150 | 165 |

| inlet temperature(oC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| material temperature(oC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

40-60 |

40-60 | 40-60 | 40-60 |

| Overall dimensions (main unit) L×W×H(m) | 8×1 | 10×1 | 12×1.2 | 4×1.2 | 8×1.2 | 8×1.2 | 10×1.2 | 12×1.2 | 14×1.2 | 16×1.2 | 18×1.2 |

| footprint (of a building, piece of equipment etc)(m2) | 74×3.58 | 82×3.58 | 96×4.1 | 50×4.1 | 70×4.1 | 82×4.1 | 100×4.1 | 140×4.1 | 180×4.1 | 225×4.1 | 268×4.1 |

Note: I. Feeding method: 1. star feeding; 2. star feeding type and pneumatic conveying and use; 3. belt conveying; 4. user-defined.

II. Automatic production can be realised. iii. In addition to the above models, we can make special design for users. IV. According to different materials, the power of the fan is also different.

Previous: Vacuum Belt Dryer

Recently, in the production workshop of Changzhou Haihan Drying Equipment Technology Co., Ltd., a large vacuum disc dryin…

Fluidization technology originated in 1921 and was first applied to large-scale industrial production of drying. It was e…

How do the design parameters (frequency, amplitude) of vibration motors or eccentric blocks affect the fluidization effec…

Take a screenshot and recognize the QR code

Haihan Drying Equipment