Category: Multifunctional filtering, washing and drying equipment series

Introduction: OutlinedIt is a multifunctional solid-liquid separation equipment integrating stirring, mixing, filtering and washing, which is widely used in chemical, food, printing and dyeing, pharmaceutical and other industries. Its main components include rotati…

+86-13906119320

+86-13906119320

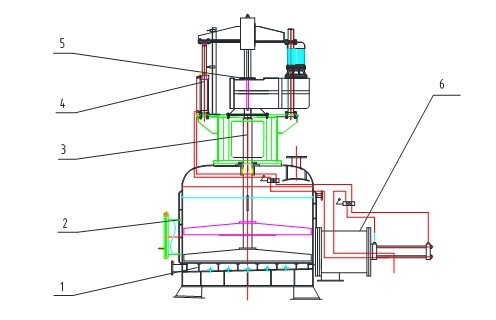

The filter press is mainly composed of a rotating device, a filtering unit, a stirring system, a lifting mechanism, a slag discharge mechanism, a filter bed and other components. Its structure is shown in the figure

|

model number |

Nominal filtration area (m²) |

Nominal capacity(m³) |

Cylinder diameter (mm) |

Cylinder height(mm) |

work pressure |

Blade lifting height(mm) |

Cake height |

Stirring motor power(kw) |

Net weight of equipment(kg) |

|

DN1200 |

1.0 |

1.36 |

1200 |

1000 |

0-0.35 |

300 |

200 |

7.5 |

3850 |

|

DN1400 |

1.5 |

1.19 |

1400 |

1000 |

0-0.35 |

350 |

300 |

11 |

4960 |

|

DN1600 |

2.0 |

2.99 |

1600 |

1000 |

0-0.35 |

400 |

350 |

15 |

5630 |

|

DN2000 |

3.0 |

5.06 |

2000 |

1000 |

0-0.35 |

450 |

400 |

18.5 |

6850 |

|

DN2300 |

4.0 |

6.76 |

2300 |

1150 |

0-0.35 |

500 |

400 |

18.5 |

96850 |

|

DN2600 |

5.3 |

8.92 |

2600 |

1200 |

0-0.35 |

500 |

450 |

22 |

11600 |

|

DN2800 |

6.0 |

10.8 |

2800 |

1500 |

0-0.35 |

550 |

500 |

22 |

13220 |

|

DN3000 |

7.0 |

6.67 |

3000 |

1550 |

0-0.35 |

550 |

600 |

37 |

15650 |

|

DN3200 |

8.0 |

10.8 |

3200 |

1550 |

0-0.35 |

550 |

600 |

45 |

18230 |

Previous: SHYZ Series Vacuum Screw Dryer

Recently, in the production workshop of Changzhou Haihan Drying Equipment Technology Co., Ltd., a large vacuum disc dryin…

Fluidization technology originated in 1921 and was first applied to large-scale industrial production of drying. It was e…

How do the design parameters (frequency, amplitude) of vibration motors or eccentric blocks affect the fluidization effec…

Take a screenshot and recognize the QR code

Haihan Drying Equipment