I. Screw Belt Vacuum Dryer Application

Vacuum contact low temperature drying method

Mixing/Drying

Heating/Cooling

Distillation/Crystallisation/Drying

Mixing/coating and liquid injection

II. Multi-purpose

Conical screw belt vacuum mixer/dryer can be applied in many fields; it is especially suitable for process treatment in closed and controlled environment, such as pharmaceutical and chemical fields as well as additives, unstable extract crystals in air or high temperature and various pharmaceutical and biological processes, Honest Company's multi-purpose conical screw belt vacuum mixer/dryer equipment is the ideal choice to solve your production needs.

Third, high-efficiency vacuum drying

Conical screw belt vacuum mixer/dryer is a set of mixing, drying and distillation as one of the multifunctional equipment, the use of fully enclosed GMP clean design, its drying efficiency is the same specifications (Double Cone Rotary Vacuum Dryer) 3-5 times, the amount of material is (Double Cone Rotary Vacuum Dryer) 2 times, the relative effectiveness of the increase of 6-10 times. The screw belt stirrer can make the material achieve the stirring effect of bottom-up spiral circulation, and can get high efficient heat transfer characteristics, the material loading rate of 30%-100% work, can get 100% of the heating area of the use of efficiency. It is a new type of drying equipment which is energy-saving, high-efficiency, environmentally friendly and clean.

High mixing precision

High mixing precision can be achieved. Even in the same batch of products mixed with different densities and different particle shapes of materials, can also be in the cone mixer to achieve the required mixing accuracy. In a large number of materials to add a very small amount of material in such harsh process conditions, can also be mixed in the integrity of the company's conical screw belt vacuum mixer/dryer.

Five, low shear screw belt mixing

The use of low shear screw belt mixing paddle, in the low speed and low energy consumption under the gentle mixture of materials. The mixing intensity and mixing time are lower.

Suitable for viscous materials

Under the action of friction and pressure generated between the material particles during mixing, even the more viscous materials can be separated and effectively mixed.

Different material filling rate

The filling rate of conical screw belt mixer/dryer is 30%-100% of the effective working volume, in which the mixing and drying of different loading volume can get consistent results.

Sealed and clean design

Conical screw belt vacuum mixer/dryer itself is fully sealed design, all the connecting parts including feeding and discharging are fixed, can meet the material and environmental safety requirements.

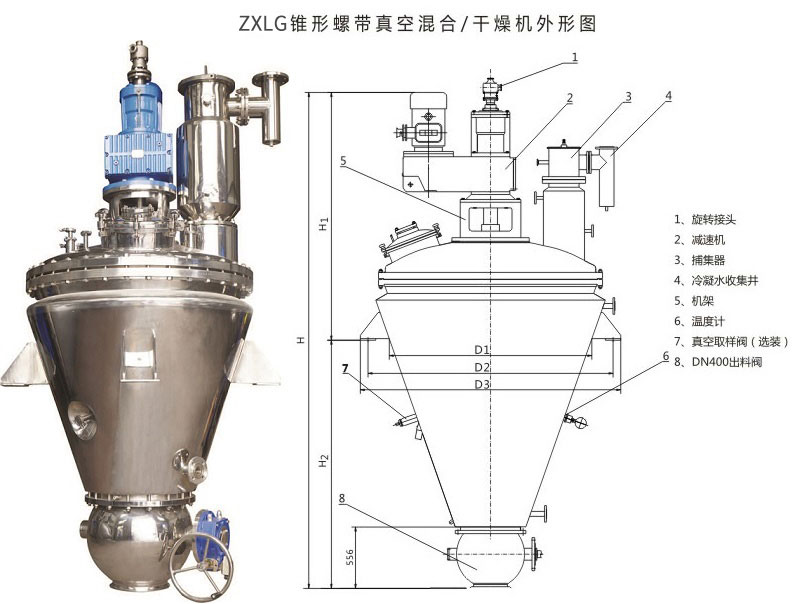

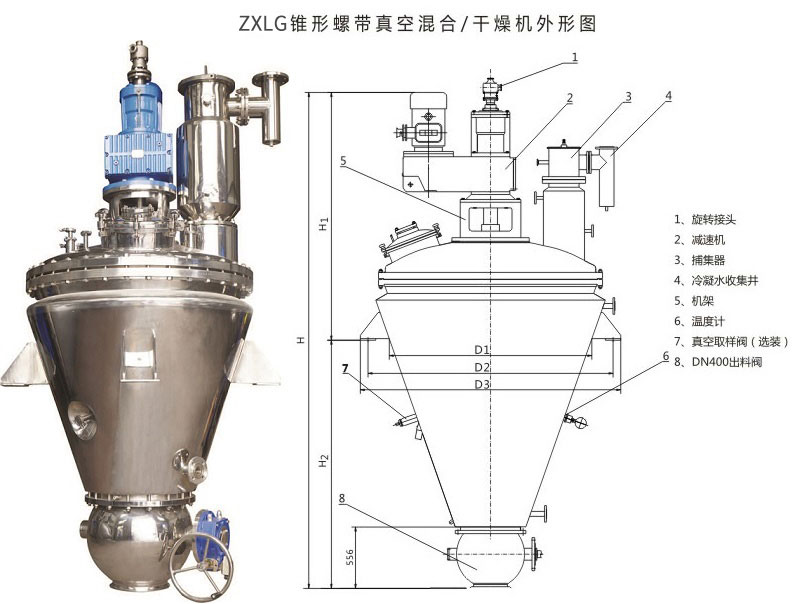

Nine, large diameter ball section discharge valve (Figure 1)

Real ball section valve

Powder, liquid and gas sealing

Eccentric shaft structure, no friction on the sealing surface

Unobstructed, fully open in the diameter direction

Hygienic and GMP-compliant design, no dead space, no residual material, easy to clean

Standard materials of construction are SUS316, SUS304 stainless steel.

No cast parts in the structure, no porosity and shrinkage defects.

Airtight bearing chamber

Standard surface finish, internal Ra0.4μm, external Ra0.8μm

Designed for full vacuum and 0.25Mpa pressure

Designed to be fed with nitrogen to facilitate vacuum drying and eliminate stirring dead space

Designed to pass cleaning liquid to clean the inside of the valve body.

Designed to be installed with filters to prevent dust from being discharged when discharging materials.

X. Vacuum Sampling Valve

真空取样阀直接与螺带内加热锥形真空干燥机连接,无任何死角,避免取样样品被污染。取样阀工作压力≤0.8Mpa,全真空,工作温度150度。The vacuum sampling valve is directly connected with the conical vacuum dryer with internal heating in the screw belt, without any dead angle, avoiding the sample being contaminated. The working pressure of the sampling valve is ≤0.8Mpa, full vacuum, and the working temperature is 150 degrees.

技术参数

|

item

|

ZXLG-500

|

ZXLG-750

|

ZXLG-1000

|

ZXLG-1250

|

ZXLG-1500

|

ZXLG-2000

|

ZXLG-3000

|

ZXLG-4000

|

|

Effective volume

|

500

|

750

|

1000

|

1250

|

1500

|

2000

|

3000

|

4000

|

|

Heating area(m2)

|

4.1

|

5.2

|

7.2

|

9.1

|

10.6

|

13

|

19

|

22

|

|

Motor power(KW)

|

5.5

|

7.5

|

7.5

|

11

|

15

|

18.5

|

22

|

30

|

|

Net weight of equipment(Kg)

|

1350

|

1850

|

2300

|

2600

|

2900

|

3600

|

4100

|

4450

|

|

stirring speed(rpm)

|

50

|

45

|

40

|

38

|

36

|

36

|

34

|

32

|

|

Total height of equipment H(m)

|

3565

|

3720

|

4165

|

4360

|

4590

|

4920

|

5160

|

5520

|

|

Height of container H3

|

1455

|

1610

|

1965

|

2160

|

2300

|

2590

|

2380

|

3160

|

|

Headstock Height H4

|

895

|

995

|

1315

|

1480

|

1630

|

1860

|

1900

|

2240

|

|

Note: Due to material differences, the data in the table is for reference only.

|

EXCLUSIVE LOGISTICS SUPPORT CUSTOMIZATION

+86-13906119320

+86-13906119320