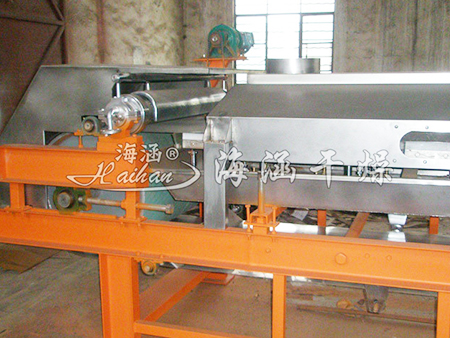

Category: Granulating, mixing and crushing machine series

Introduction: Working PrincipleRL type granulator is to use the materials melting point is lower than 250 ℃ characteristics, according to the viscosity range of the material in the molten state, through the special fabrication device will be molten liquid uniforml…

+86-13906119320

+86-13906119320

RL type granulator is to use the material's melting point is lower than 250 ℃ characteristics, according to the viscosity range of the material in the molten state, through the special fabrication device will be molten liquid uniformly in the uniform speed movement of the steel belt underneath it, in the steel belt below the setting of the cooling effect of the continuous spray device, so that the material in the conveying, moving process of the material to be cooled, curing, packaging, so as to achieve the purpose of granulation and shaping.

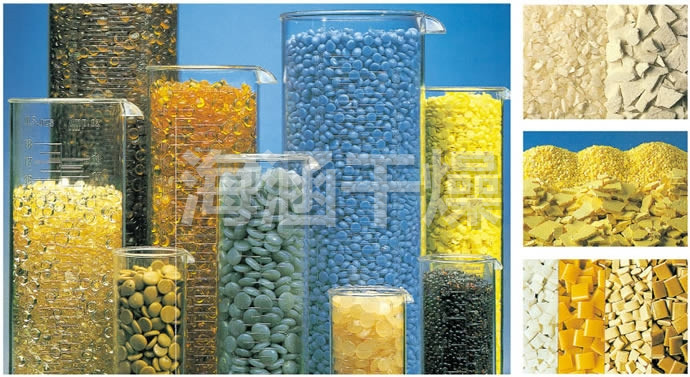

This product is suitable for all kinds of materials whose melting point (or softening point) is between 50℃-300℃ and need to be granulated, as well as materials with the characteristic of ‘subcooling crystallisation’.

| model number | RL60-A | RL60-B | RL60-C | RL60-D | RL120-A | RL120-B | RL120-C | RL120-D |

| Effective heat transfer area(m2) | 2.6 | 3.6 | 4.6 | 5.3 | 7.3 | 9.3 | 10.8 | 16.6 |

| Main/auxiliary motor power(kw) | 1.5/0.75 | 1.5/0.75 | 1.5/1.1 | 1.5/1.1 | 3/1.5 | 3/1.5 | 3/1.5 | 4/2.2 |

| Overall dimensions(mm) |

5600×1200

×1800

|

7200×1200

×1800

|

8800×1200

×1800

|

10050×1200

×1800

|

7200×1700

×1800

|

8800×1700

×1800

|

10050×1700

×1800

|

14800×1700

×1800

|

| production capacity(kg/h) | 80-100 | 100-150 | 120-180 | 150-250 | 300-380 | 360-420 | 380-500 | 500-800 |

| gross weight(kg) | 1360 | 1580 | 1880 | 2060 | 2380 | 2590 | 2830 | 4210 |

Previous: GZL series dry rolling granulator

Next: ZB Vacuum Harrow Dryer

Recently, in the production workshop of Changzhou Haihan Drying Equipment Technology Co., Ltd., a large vacuum disc dryin…

Fluidization technology originated in 1921 and was first applied to large-scale industrial production of drying. It was e…

How do the design parameters (frequency, amplitude) of vibration motors or eccentric blocks affect the fluidization effec…

Take a screenshot and recognize the QR code

Haihan Drying Equipment