Category: Granulating, mixing and crushing machine series

Introduction: Working PrincipleRoller extrusion granulation process principle is: dry material under pressure agglomeration into dense and hard chunks (cake), known as the extrusion process; cake and then crushed and sifted to become granular material known as the …

+86-13906119320

+86-13906119320

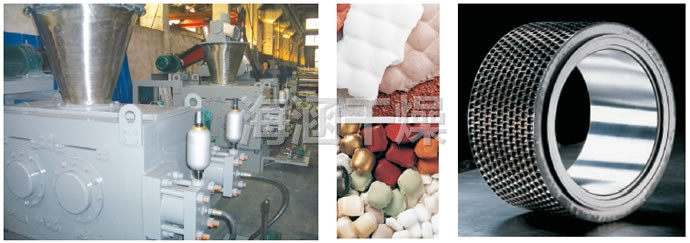

Roller extrusion granulation process principle is: dry material under pressure agglomeration into dense and hard chunks (cake), known as the extrusion process; cake and then crushed and sifted to become granular material known as the granulation process. The role of extrusion is to squeeze out the air between the particles, the other is to make the particle spacing to reach close enough to produce such as van der Waals force, adsorption, crystal bridges and embedded connections and other attractive forces. The strength of extruded pellets is mainly due to the forces between molecules that form the pellets.

Extrusion pelletising is a relatively new dry pelletising process for the production of compound fertilisers. Extruded pelleting in the field of fertilizers was applied to the pelleting of potassium chloride at the beginning, and the granular (1-4mm) potassium chloride required for blended fertilizers (BB fertilizers) was basically produced by extruding method. In recent years, extrusion granulation for the production of compound fertilisers has been developed rapidly in China.

The form of extrusion granulation can have two kinds of roller type and wheel rolling type, roller type extrusion is first pressed into a large block, and then crushed into particles, so that the capacity of the device is large, high strength particles, low energy consumption, roller extrusion is widely used in foreign countries. Roller type is made directly on the surface of the rollers with a cavity groove shape, once extruded into moulded particles. The strength of the product is low, sometimes need to add binder. It is suitable for making organic fertiliser and compound fertiliser and other granular fertiliser.

| model number | Pressure roller centre distance | power |

| GZL-240 | 240 | 7.5-1.5 |

| GZL-360 | 360 | 22-45 |

| GZL-460 | 460 | 37-60 |

| GZL-580 | 580 | 45-90 |

| GZL-650 | 650 | 55-200 |

| GZL-730 | 730 | 90-315 |

On 18th April, 2025, 4 sets of FZG series square vacuum dryers customised by Changzhou Haihan Drying Equipment Technology…

Exhibition Name: The 25th International Agricultural Chemicals and Plant Protection ExhibitionExhibition time: March 17-1…

In this hopeful and vibrant Year of the Snake, Changzhou Haihan Drying Equipment Technology Co., Ltd. welcomed a grand gr…

Take a screenshot and recognize the QR code

Haihan Drying Equipment