Category: Closed Circuit Dryer Series

Introduction: Closed Circuit Flash Vapour Dryer is mainly used for processing materials containing organic solvents or materials that are toxic, harmful and easy to oxidise. The working principle is that the hot medium (such as nitrogen and other inert gases) is ci…

+86-13906119320

+86-13906119320

Closed Circuit Flash Vapour Dryer is mainly used for processing materials containing organic solvents or materials that are toxic, harmful and easy to oxidise. The working principle is that the hot medium (such as nitrogen and other inert gases) is circulated in a closed loop system. The material is dried rapidly as the hot medium passes through it. Advantages include the effective avoidance of material oxidation and explosion risks, reduced organic solvent emissions, protection of the environment and operator safety. Moreover, the closed loop design reduces material loss, improves product recovery, has a high drying efficiency and can quickly evaporate water or other solvents from the material.

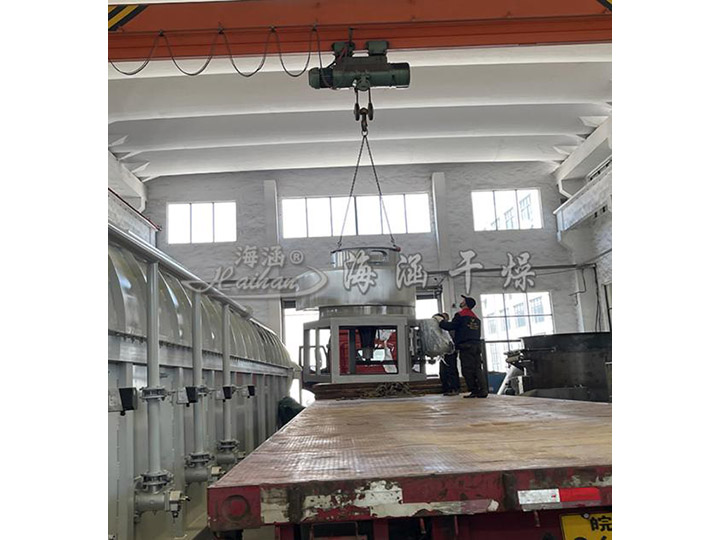

Two sets of three-dimensional mixer professionally manufactured by Hoi Han Drying have been successfully shipped to the c…

Each kind of drying device has its specific scope of application, and each kind of material can find a number of drying d…

Dear customers and partners: The Dragon Boat Festival is approaching in the middle of summer, and the time is clear and…

Take a screenshot and recognize the QR code

Haihan Drying Equipment