Category: Drying equipment series

Introduction: Working PrincipleHollow paddle dryer is a kind of horizontal stirring type continuous drying equipment mainly based on heat conduction. Because the heat required for drying relies on indirect heating by heat conduction, the drying process does not nee…

+86-13906119320

+86-13906119320

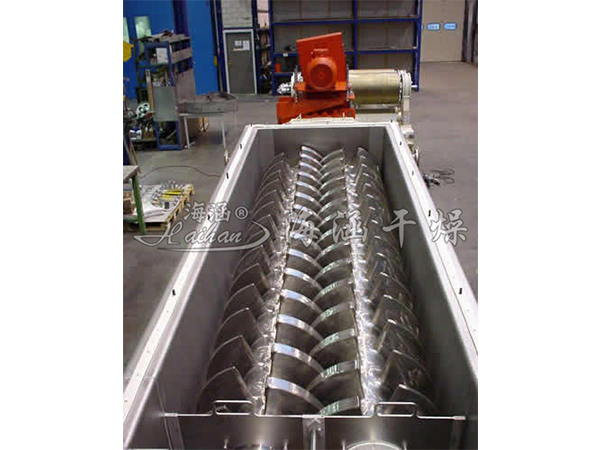

Hollow paddle dryer is a kind of horizontal stirring type continuous drying equipment mainly based on heat conduction. Because the heat required for drying relies on indirect heating by heat conduction, the drying process does not need or only needs a small amount of gas to take away the moisture. It greatly reduces the part of heat loss taken away by gas flow, improves the heat utilisation rate, and is a kind of energy-saving drying equipment. Paddle dryer is widely used in petrochemical, chemical, metallurgy, food, medicine, pesticide and other industries in the powder, granular, filter cake, slurry material drying.

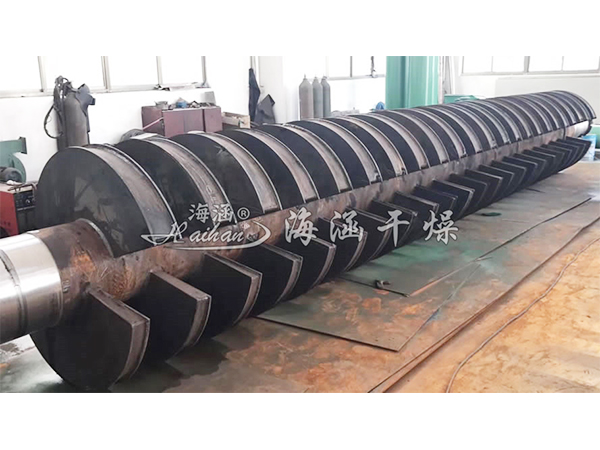

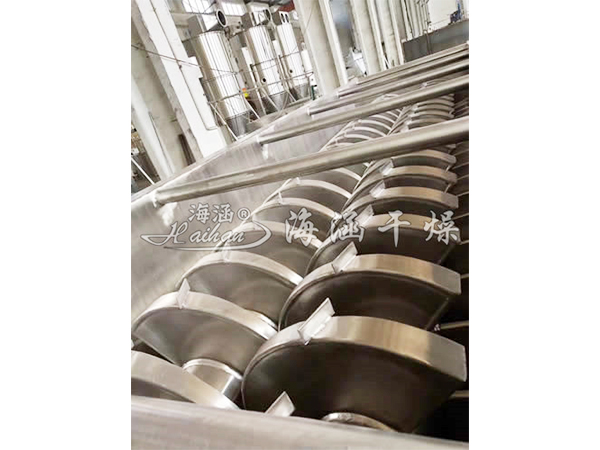

The heat transfer surface of the hollow paddle dryer has several parts such as blade, stirring shaft and wall, and the heat transfer area of the blade accounts for a large part, so the equipment has a compact structure and a large heat transfer area per unit volume. In addition, stirring and mixing make the material flip violently, so as to obtain a high heat transfer coefficient, so the floor space and space are very small, saving the cost of plant infrastructure. Drying process gas dosage is less, the flow rate is low, the amount of dust taken away by the gas is less, so it is convenient to recover the gas dust after drying, and the volume of the recovery equipment is small, so it can save the investment in equipment. For the drying process which needs to recover solvent, the concentration of solvent can be greatly improved. Due to the special structure of paddle, the material receives squeezing and relaxation alternately in the drying process, which strengthens the drying. The filling rate of the material inside the drying chamber is very high, which can reach 80%-90%, and the residence time of the material can be adjusted by adjusting the charging speed, stirring shaft rotation speed, the filling degree of the material and other parameters, which can be adjusted arbitrarily from a few minutes to a few hours. In addition, the material in the dryer from the feeding port to the discharge port movement is basically a piston movement, residence time distribution is narrow, so the product moisture content is uniform. The paddle has a certain axial angle on the mixing shaft, so the material can be dried continuously.

Paddle dryers have been successfully used in the fields of foodstuffs, chemicals, petrochemicals, dyestuffs and industrial sludge. The heat transfer, cooling and stirring characteristics of the equipment enable it to perform the following unit operations: calcination (low temperature), cooling, drying (solvent recovery), heating (melting), reaction and sterilisation. Stirring The paddles are also heat transfer surfaces, which increases the heat transfer area per effective volume and shortens the processing time. The wedge-shaped paddle heat transfer surface is also self-cleaning. Compression-expansion stirring function to make the material mix evenly. Material along the axial into the ‘piston flow’ movement, in the axial zone, the material temperature, humidity, mixing degree gradient is very small.

With thermal oil as the heat medium, paddle dryer can complete the low-temperature calcination work. For example: Calcium sulfate dihydrate (CaSO4-2H2O) calcined into calcium sulfate hemihydrate (CaSO4-1/2H2O). Sodium bicarbonate (NaHCO3) calcined into soda ash (Na2CO3) and so on.

Cooling medium, such as water, cooling brine, etc. can be used for cooling. For example, the paddle-type cooling machine used in the soda ash industry replaces the old-fashioned air-cooled cooling machine, which saves energy and exhaust gas treatment equipment, reduces operating costs, and can also be used for titanium dioxide, nickel-iron alloy powder and a variety of powdered and granular materials cooling. In a single machine can be cooled from 1000 ℃ material to less than 40 ℃.

Drying, the most important function of the equipment, does not use hot air, so that solvent recovery, energy consumption, environmental control in an ideal state of easy to handle. The need to recover solvents, flammable and easy to oxidise heat-sensitive materials are particularly adaptable. Has been widely used in fine chemicals, petrochemicals, dyes industry.

The uniformity of temperature, humidity and mixing in the axial zone makes the equipment usable for heating or melting, or for some solid material reactions. It has been successfully used in compound fertiliser and modified starch industries. Paddle dryers can be used to sterilise food and flour. The large heating area in the unit effective volume quickly heats the material to the sterilisation temperature, avoiding the change of material quality by long time heating.

1、Petrochemical industry: polyolefin powder, polycarbonate resin, high and low density polyethylene, linear low density polyethylene, polyacetal particles, nylon 6, nylon 66, nylon 12, acetate fibre, polyphenylene sulphide, propylene-based resins, engineering plastics, polyvinyl chloride, polyvinyl alcohol, polystyrene, polypropylene, polyester, polyformaldehyde, styrene ~ acrylonitrile copolymer, ethylene ~ propylene copolymer.

2、Environmental protection industry: PTA sludge, electroplating sewage sludge, boiler soot, pharmaceutical factory slag, sugar factory slag, monosodium glutamate factory slag, coal ash.

3、Feed industry: soy sauce residue, bone-based feed, wine lees, food scraps, apple pomace, orange peel, soybean meal, chicken bone feed, fish meal, feed additives, biological sludge.

4、Food industry: starch, cocoa beans, corn kernels, salt, modified starch, pharmaceuticals.

5、Chemical industry: soda ash, nitrogen, phosphorus and potassium compound fertilizer, kaolin, bentonite, white carbon black, carbon black, phosphogypsum, sodium oxide fluoride, nitric acid, calcium, magnesium carbonate, sodium cyanide, aluminium hydroxide, barium sulphate, calcium sulphate, calcium carbonate, dyes, molecular sieve, saponin.

|

Item

Model |

JYG3 | JYG9 | JYG13 | JYG18 | JYG29 | JYG41 | JYG52 | JYG68 | JYG81 | JYG95 | JYG110 |

| heat transfer area(m2) | 3 | 9 | 13 | 18 | 29 | 41 | 52 | 68 | 81 | 95 | 110 |

| effective volume(m3) | 0.06 | 0.32 | 0.59 | 1.09 | 1.85 | 2.8 | 3.96 | 5.21 | 6.43 | 8.07 | 9.46 |

| Speed range(rmp) | 15-30 | 10-25 | 10-25 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 5-15 | 5-15 | 5-10 |

| power (output) (kw) | 2.2 | 4 | 5.5 | 7.5 | 11 | 15 | 30 | 45 | 55 | 75 | 95 |

| body width A(mm) | 306 | 584 | 762 | 940 | 1118 | 1296 | 1474 | 1652 | 1828 | 2032 | 2210 |

| total width B(mm) | 736 | 841 | 1066 | 1320 | 1474 | 1676 | 1854 | 2134 | 1186 | 2438 | 2668 |

| body width C(mm) | 1956 | 2820 | 3048 | 3328 | 4114 | 4724 | 5258 | 5842 | 6020 | 6124 | 6122 |

| overall length D(mm) | 2972 | 4876 | 5486 | 5918 | 6808 | 7570 | 8306 | 9296 | 9678 | 9704 | 9880 |

| In/Out Distance E(mm) | 1752 | 2540 | 2768 | 3048 | 3810 | 4420 | 4954 | 5384 | 5562 | 5664 | 5664 |

| centre height F(mm) | 380 | 380 | 534 | 610 | 762 | 915 | 1066 | 1220 | 1220 | 1220 | 1220 |

| total height H(mm) | 762 | 838 | 1092 | 1270 | 1524 | 1778 | 2032 | 2362 | 2464 | 2566 | 2668 |

| inlet N(寸) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 11/2 | 11/2 | 11/2 | 11/2 | 2 |

| drainage outlet O(寸) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 11/2 | 11/2 | 11/2 | 11/2 | 2 |

Previous: High speed centrifugal spray dryer

Two sets of three-dimensional mixer professionally manufactured by Hoi Han Drying have been successfully shipped to the c…

Each kind of drying device has its specific scope of application, and each kind of material can find a number of drying d…

Dear customers and partners: The Dragon Boat Festival is approaching in the middle of summer, and the time is clear and…

Take a screenshot and recognize the QR code

Haihan Drying Equipment