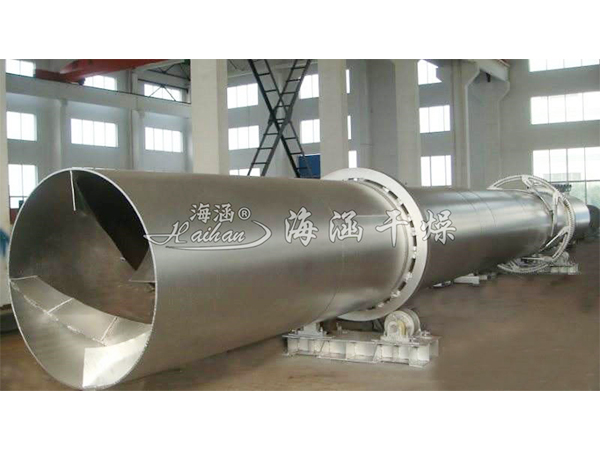

Category: Drying equipment series

Introduction: Working PrincipleThe rotary kiln dryer is used for the pre-firing of hard magnetic ferrite powder, and can also be applied to cement, metallurgy, chemical industry and other industries. The equipment consists of main kiln and its supporting transmissi…

+86-13906119320

+86-13906119320

The rotary kiln dryer is used for the pre-firing of hard magnetic ferrite powder, and can also be applied to cement, metallurgy, chemical industry and other industries. The equipment consists of main kiln and its supporting transmission device, cooling pipe, fuel system, electrical control, secondary air inlet device, exhaust dust removal device and preheating kiln body. It has the functions of over-temperature alarm, overload alarm, automatic control of working temperature and adjustable oxygen inside the kiln.

Wet materials from the dryer into one end, in the cylinder uniformly distributed under the flap, the material in the dryer evenly distributed and dispersed, and with the parallel flow (countercurrent) of the hot air fully in contact with the drying of heat transfer, mass transfer to accelerate the driving force. In the process of drying, the material is under the action of the tilting platen and hot air flow, and can be adjusted to move to the other section of the dryer to discharge the finished products through the star-shaped discharge valve.

| formality |

Direct heating

Downflow

|

Direct heating

Downflow

|

Direct heating

Countercurrent

|

Direct heating

Countercurrent

|

Combined heating |

Combined heating |

|

Material Type |

ores |

HP foaming agent |

blast furnace slag (mining) |

ammonium sulphur |

phosphate fertiliser |

coal |

|

treatment capacity(kg/h) |

1000 |

466 |

15000 |

20000 |

12000 |

5000 |

|

initial moisture content(%) |

30 |

13 |

6 |

1.5 |

5 |

6.5 |

|

final moisture content(%) |

15 |

0.3 |

1 |

0.1 |

0.1 |

0.1 |

|

Average particle size(mm) |

6.5 |

0.05 |

4.7 |

0.5-1.7 |

0.5 |

5 |

|

Material stacking weight(kg/m3) |

770 |

800 |

1890 |

1100 |

1500 |

750 |

|

hot air volume(kg/h) |

39000 |

5400 |

10750 |

9800 |

6500 |

16000 |

|

Inlet gas temperature(℃) |

600 |

165 |

500 |

180 |

650 |

570 |

|

Material outlet temperature(℃) |

|

42 |

100 |

70 |

80 |

75 |

|

Heating method |

gas (fuel) |

Steam electric heating |

heavy oil |

Coal-fired heaters |

heavy oil |

heavy oil |

|

Charging factor |

|

6.3 |

7 |

7.5 |

7.8 |

18 |

|

number of revolutions per minute(rpm) |

4 |

4 |

3.5 |

3 |

4 |

2 |

|

inclination (from the horizontal or vertical) |

0.04 |

0.005 |

0.03 |

0.05 |

0.05 |

0.043 |

|

Number of copy boards |

12 |

24 |

12 |

22 |

Outside of inner cylinder 8

Inner surface of outer cylinder 16

|

Outer face of inner cylinder 6

|

|

Dryer Diameter(m) |

2.0 |

1.5 |

2 |

2.3 |

Outer cylinder 2

Inner Cylinder 0.84

|

Outer cylinder 2.4

Inner cylinder 0.95

|

|

Dryer length(m) |

20 |

12 |

17 |

15 |

10 |

16 |

|

driving power(kw) |

22 |

7.5 |

15 |

11 |

11 |

15 |

Previous: GFG High Efficiency Boiling Dryer

Next: Pharmaceutical GMP Oven

Two sets of three-dimensional mixer professionally manufactured by Hoi Han Drying have been successfully shipped to the c…

Each kind of drying device has its specific scope of application, and each kind of material can find a number of drying d…

Dear customers and partners: The Dragon Boat Festival is approaching in the middle of summer, and the time is clear and…

Take a screenshot and recognize the QR code

Haihan Drying Equipment