Category: Drying equipment series

Introduction: Working PrincipleWet material from the feeder continuously added to the dryer on the first layer of the upper drying disc, with a rake leaf rake arm for rotary movement so that the rake arm for rotary movement so that the rake leaf continuous plunge m…

+86-13906119320

+86-13906119320

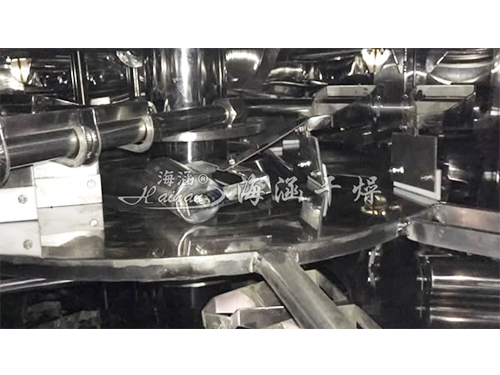

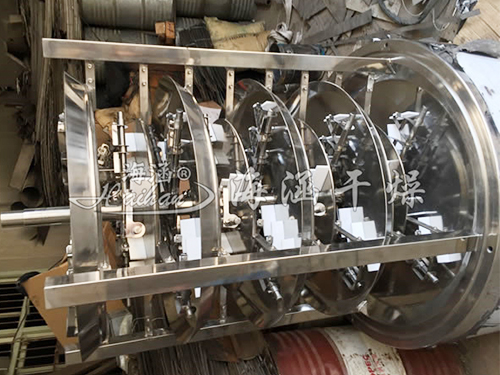

Wet material from the feeder continuously added to the dryer on the first layer of the upper drying disc, with a rake leaf rake arm for rotary movement so that the rake arm for rotary movement so that the rake leaf continuous plunge material. The material flows through the surface of the drying disc along the index helix, and the material on the small drying disc is moved to the outer edge, and falls to the outer edge of the large drying disc below the outer edge of the large drying disc, and the material on the large drying disc moves inwardly and falls down to the next layer of small drying discs from the middle of the material falling mouth. The size of the drying discs arranged alternately up and down, the material to flow continuously through the entire dryer. The hollow drying disc passes into the heating medium, the form of heating medium has saturated steam, hot water and heat-conducting oil, the heating medium enters from one end of the drying disc, and leads out from the other end. The dried material falls to the bottom of the shell from the latter layer of drying disc, and then is moved to the discharge port by the rake leaves. Moisture escapes from the material, and is discharged by the moisture discharge port located on the top cover, and the moisture of the vacuum-type disc dryer is discharged by the vacuum pump port located on the top cover. The dry material discharged from the bottom can be packed directly. By adding fin heater, solvent recovery condenser, bag-type dust collector, dry material re-mixing mechanism, induced draft fan and other auxiliary machines, it can improve its drying production capacity, drying paste and heat-sensitive materials, can be convenient to recover solvents, and can carry out pyrolysis and reaction operations.

| norm | external diameter mm | high mm | Drying area m2 | power Kw |

| 1200/4 | 1850 | 2608 | 3.3 | 1.1 |

| 1200/6 | 3028 | 4.9 | ||

| 1200/8 | 3448 | 6.6 | 1.5 | |

| 1200/10 | 3868 | 8.2 | ||

| 1200/12 |

4288 |

9.9 | 2.2 | |

| 1500/6 | 2100 | 3022 | 8.0 | |

| 1500/8 | 3442 | 10.7 | ||

| 1500/10 | 3862 | 13.4 | ||

| 1500/12 | 4282 | 16.1 | 3.0 | |

| 1500/14 | 4702 | 18.8 | ||

| 1500/16 | 5122 | 21.5 | ||

| 2200/6 | 2900 | 3262 | 18.5 | |

| 2200/8 | 3682 | 24.6 | ||

| 2200/10 | 4102 | 30.8 | 4.0 | |

| 2200/12 | 4522 | 36.9 | ||

| 2200/14 | 4942 | 43.1 | 5.5 | |

| 2200/16 | 5362 | 19.3 | ||

| 2200/18 | 5782 | 55.4 | 7.5 | |

| 2200/20 | 6202 | 61.6 | ||

| 2200/22 | 6622 | 67.7 | 11 | |

| 2200/24 | 7042 | 73.9 | ||

| 2200/26 | 7462 | 80.0 |

| norm | external diameter mm | high mm | Drying area m2 | power Kw |

| 2500/6 | 3150 | 3319 | 26.3 | 4 |

| 2500/8 | 3739 | 35 | ||

| 2500/10 | 4159 | 43.8 | 5.5 | |

| 2500/12 | 4579 | 52.5 | ||

| 2500/14 | 4999 | 61.3 | 7.5 | |

| 2500/16 | 5419 | 70 | ||

| 2500/18 | 5839 | 78.8 | 11 | |

| 2500/20 | 6259 | 87.5 | ||

| 2500/22 | 6679 | 96.3 | ||

| 2500/24 | 7099 | 105 | 13 | |

| 2500/26 | 7519 | 113.8 | ||

| 3000/8 | 3800 | 4050 | 48 | 11 |

| 3000/10 | 4650 | 60 | ||

| 3000/12 | 5250 | 72 | ||

| 3000/14 | 5850 | 84 | ||

| 3000/16 | 6450 | 96 | ||

| 3000/18 | 7050 | 108 | 15 | |

| 3000/20 | 7650 | 120 | ||

| 3000/22 | 8250 | 132 | ||

| 3000/24 | 8850 | 144 | ||

| 3000/26 | 9450 | 156 | 18 | |

| 3000/28 | 10050 |

168 |

Previous: Circular Vacuum Dryer

Two sets of three-dimensional mixer professionally manufactured by Hoi Han Drying have been successfully shipped to the c…

Each kind of drying device has its specific scope of application, and each kind of material can find a number of drying d…

Dear customers and partners: The Dragon Boat Festival is approaching in the middle of summer, and the time is clear and…

Take a screenshot and recognize the QR code

Haihan Drying Equipment