Category: Multifunctional filtering, washing and drying equipment series

Introduction: OutlinedFiltering, washing and drying three-in-one equipment is a kind of equipment integrating filtration, washing and drying functions, which is widely used in pharmacy, chemical industry, foodstuff, dyestuff and other industries. The equipment co…

+86-13906119320

+86-13906119320

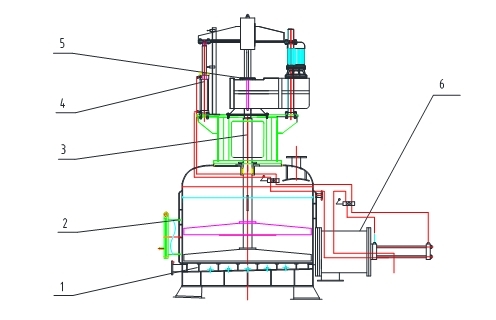

The multifunctional filtration washing and drying machine is mainly composed of rotating device, multifunctional filtration unit, mixing system, lifting mechanism, slag discharge mechanism, filtration system and other components. Its structure is shown in the figure.

|

model number |

Nominal filtration area (m²) |

Nominal capacity(m³) |

Cylinder diameter (mm) |

Cylinder height(mm) |

work pressure |

Blade lifting height(mm) |

Cake height |

Stirring motor power(kw) |

Net weight of equipment(kg) |

|

DN500 |

0.19 |

0.4 |

500 |

600 |

-0.1~0.35 |

150 |

120 |

2.2 |

1350 |

|

DN600 |

0.28 |

0.26 |

600 |

750 |

-0.1~0.35 |

150 |

120 |

3.0 |

1560 |

|

DN800 |

0.52 |

0.53 |

800 |

900 |

-0.1~0.35 |

300 |

200 |

5.5 |

2230 |

|

DN1200 |

1.0 |

1.36 |

1200 |

950 |

-0.1~0.35 |

300 |

250 |

7.5 |

4300 |

|

DN1400 |

1.5 |

1.19 |

1400 |

1100 |

-0.1~0.35 |

350 |

300 |

11 |

5890 |

|

DN1600 |

2.0 |

2.99 |

1600 |

1200 |

-0.1~0.35 |

400 |

350 |

15 |

6630 |

|

DN2000 |

3.0 |

5.06 |

2000 |

1200 |

-0.1~0.35 |

450 |

400 |

18.5 |

11350 |

|

DN2300 |

4.0 |

6.76 |

2300 |

1250 |

-0.1~0.35 |

500 |

450 |

18.5 |

13850 |

|

DN2800 |

6.0 |

10.8 |

2800 |

1250 |

-0.1~0.35 |

500 |

450 |

22 |

16300 |

|

DN3000 |

7.0 |

14.8 |

3000 |

1550 |

-0.1~0.35 |

550 |

600 |

37 |

18650 |

|

DN3200 |

8.0 |

16.8 |

3200 |

1550 |

-0.1~0.35 |

550 |

600 |

45 |

21230 |

Two sets of three-dimensional mixer professionally manufactured by Hoi Han Drying have been successfully shipped to the c…

Each kind of drying device has its specific scope of application, and each kind of material can find a number of drying d…

Dear customers and partners: The Dragon Boat Festival is approaching in the middle of summer, and the time is clear and…

Take a screenshot and recognize the QR code

Haihan Drying Equipment