Source: 本站 | Release date: 2023-11-25 10:19:52 | View: 38

Summary:

Changzhou Haihan Drying Equipment Technology Co., Ltd. is a set of drying, granulation, crushing, filtration as one of the modern drying enterprise, our company is equipped with prototype supply to material test, and there will be a professional techn…

Changzhou Haihan Drying Equipment Technology Co., Ltd. is a set of drying, granulation, crushing, filtration as one of the modern drying enterprise, our company is equipped with prototype supply to material test, and there will be a professional technician for you to solve the problem, welcome to my company to visit!

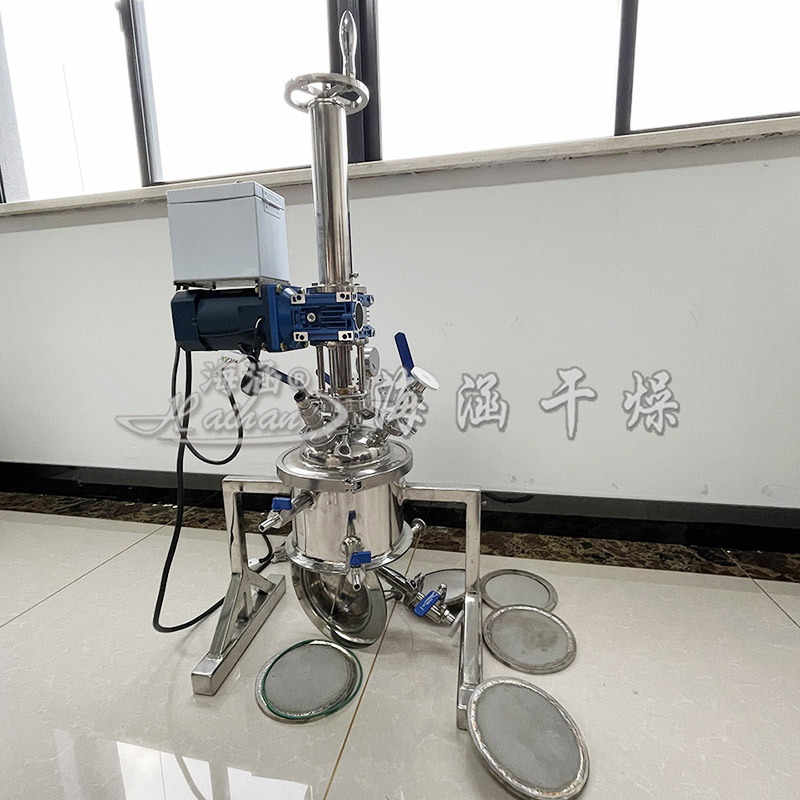

Filtering and washing two-in-one description

This equipment is a kind of solid-liquid separation equipment with high efficiency, energy saving and sealed operation. It is widely used in chemical and pesticide powder manufacturing.

The main structure and working principle of filter washing 2-in-1

The filter press is mainly composed of rotating device, filter unit, mixing system, lifting mechanism, slag discharge mechanism, filter bed and other systems and other components.

There is a filter bed system installed inside the filter press, which consists of support fascia board, filter porous plate, polypropylene filter cloth (filtration precision 10~15μm), PTFE sealing pressure strip, five filter cloth pressure rings and so on. When filtering, the material liquid to be filtered enters from the inlet of the upper head, the lower part of the filter bed is under vacuum, and the upper part is under atmospheric pressure or 0.2MPa working pressure for material filtration. There is a stirring shaft with stirrer in the upper part of the filter bed system of the press filter, this spiral stirrer can be used to stir the material or unload the filter cake when it stirs in clockwise direction, when it stirs in anticlockwise direction, it can make the surface of the filter cake become smooth and make the cracks polymerise, and it can slightly extrude the filter cake when it slows down and operates in anticlockwise direction. At the same time, the agitator can be raised or lowered by the operation of the power pack and the hydraulic control valve with two hydraulic cylinders. The operator can operate accurately through the nearby sight glass observation port, and also can clearly observe the amplitude and rate of agitator blade work. When the material filtration is finished, release the pressure inside the filter, open the slag discharge valve, and then through the operation of the control valve of the lifting cylinder and the main motor controller, make the agitator slowly descend and rotate clockwise, the filter cake will be slowly scraped down and discharged automatically.

Description of three-in-one dryer

This equipment is a small experimental prototype of solid-liquid separation equipment that combines high efficiency, energy saving and sealed operation. Mostly used in medicine, chemical industry, pesticide powder manufacturing small test.

The main structure of three-in-one dryer

Three-in-one filter is mainly composed of rotating device, filtering device, mixing system, lifting mechanism, fastening device and other systems and other components.

Two sets of three-dimensional mixer professionally manufactured by Hoi Han Drying have been successfully shipped to the c…

Dear customers and partners: The Dragon Boat Festival is approaching in the middle of summer, and the time is clear and…

Exhibition Name: The 9th (Zibo) Chemical Technology and Equipment ExhibitionExhibition time: 16th May - 18th May 2025 …

Take a screenshot and recognize the QR code

Haihan Drying Equipment