Category: Drying equipment series

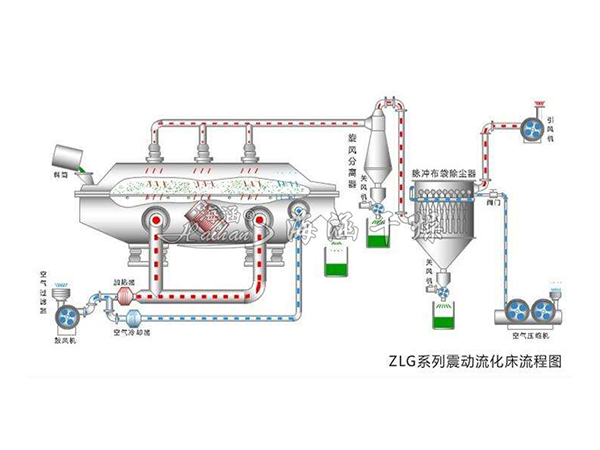

Introduction: Working PrincipleThe material enters into the machine from the feeding port, and under the action of vibration force, the material is thrown forward continuously along the horizontal direction. The hot air passes upward through the fluidised bed and t…

+86-13906119320

+86-13906119320

The material enters into the machine from the feeding port, and under the action of vibration force, the material is thrown forward continuously along the horizontal direction. The hot air passes upward through the fluidised bed and the wet material exchanges heat, the wet air is discharged by the exhaust port after the cyclone separator removes dust, and the dry material is discharged by the discharge port.

|

model number (ZLG) |

lengths |

breadth |

total width |

Lower bed height |

Upper Bed height |

total height |

weights(kg) |

|

3×0.3 |

3000 |

300 |

1350 |

900 |

430 |

1650 |

1250 |

|

4.5×0.3 |

4500 |

300 |

1350 |

900 |

430 |

1650 |

1560 |

|

4.5×0.45 |

4500 |

450 |

1550 |

950 |

430 |

1700 |

1670 |

|

4.5×0.6 |

4500 |

600 |

1650 |

950 |

430 |

1700 |

1910 |

|

6×0.45 |

6000 |

450 |

1650 |

950 |

430 |

1700 |

2100 |

|

6×0.6 |

6000 |

600 |

1700 |

1000 |

500 |

1700 |

2410 |

|

6×0.75 |

6000 |

750 |

1850 |

1000 |

600 |

1850 |

2340 |

|

6×0.9 |

6000 |

900 |

3000 |

1000 |

600 |

1850 |

3160 |

|

7.5×0.6 |

7500 |

600 |

1850 |

1000 |

600 |

1850 |

3200 |

|

7.5×0.75 |

7500 |

750 |

2000 |

1000 |

600 |

1850 |

3600 |

|

7.5×0.9 |

7500 |

900 |

2100 |

100 |

600 |

1850 |

4140 |

|

7.5×1.2 |

7500 |

1200 |

2500 |

1150 |

800 |

2050 |

5190 |

|

model number (ZLG) |

Fluidised bed area (㎡) |

inlet temperature (℃) |

outlet temperature (℃) |

Water evaporation capacity (kg/h) |

Vibration motors |

|

|

model number |

power(k w) |

|||||

|

3×0.3 |

0.9 |

70-140 |

40-70 |

20-35 |

ZDS31-6 |

0.8×2 |

|

4.5×0.3 |

1.35 |

70-140 |

40-70 |

35-50 |

ZDS31-6 |

0.8×2 |

|

4.5×0.45 |

2.025 |

70-140 |

40-70 |

50-70 |

ZDS32-6 |

1.1×2 |

|

4.5×0.6 |

2.7 |

70-140 |

40-70 |

70-90 |

ZDS32-6 |

1.1×2 |

|

6×0.45 |

2.7 |

70-140 |

40-70 |

80-100 |

ZDS41-6 |

1.5×2 |

|

6×0.60 |

3.6 |

70-140 |

40-70 |

100-130 |

ZDS41-6 |

1.5×2 |

|

6×0.75 |

4.5 |

70-140 |

40-70 |

120-140 |

ZDS42-6 |

2.2×2 |

|

6×0.9 |

5.4 |

70-140 |

40-70 |

140-170 |

ZDS42-6 |

2.2×2 |

|

7.5×0.6 |

4.5 |

70-140 |

40-70 |

130-150 |

ZDS42-6 |

2.2×2 |

|

7.5×0.75 |

5.625 |

70-140 |

40-70 |

150-180 |

ZDS51-6 |

3.0×2 |

|

7.5×0.9 |

6.75 |

70-140 |

40-70 |

160-210 |

ZDS51-6 |

3.0×2 |

|

7.5×1.2 |

9 |

70-140 |

40-70 |

200-260 |

ZDS51-6 |

3.7×2 |

Two sets of three-dimensional mixer professionally manufactured by Hoi Han Drying have been successfully shipped to the c…

Each kind of drying device has its specific scope of application, and each kind of material can find a number of drying d…

Dear customers and partners: The Dragon Boat Festival is approaching in the middle of summer, and the time is clear and…

Take a screenshot and recognize the QR code

Haihan Drying Equipment